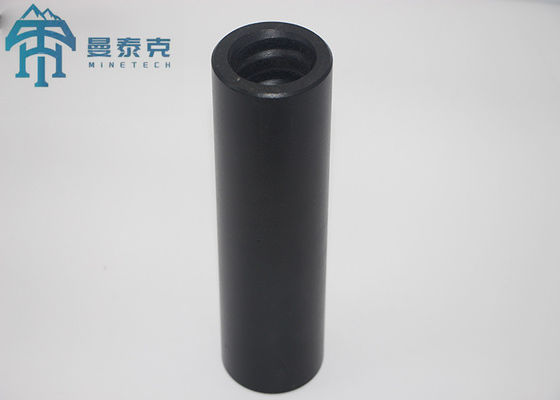

High Performance Thread Drill Rod Customized Carbon Steel

High-Performance Threaded Drilling Equipment With Customized Features

Extension rods, also referred to as Extension drill steel, Extension drill rod, and Extension steel, are rods that come in both Hexagonal and round cross sections. Hexagonal rods are known for being more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods, which are generally lighter than hexagonal rods, are primarily used in extension drilling applications.

Key Features

Carburization is often used in the heat treatment process for Extension Rod and M/F steel, in order to enhance both the power and speed of these drill string components and also maximize their performance and reliability.

The Carburization process effectively hardens the entire surface of the rod from inside to outside. This strengthens and increases the longevity of the rod. Surface carbon levels are augmented to achieve specified solidity and required hardening depth.

Technical Specifications

| Thread Type |

R22, R25, R28, R32, R38, T38, T45, T51 |

| Diameter |

Hex 25, Hex 28, Hex 32, Hex 35, RD 39, RD 46, RD 52 |

| Rod Type |

Round type and hexagonal type |

| Material |

High strength alloy steel imported from top level steel manufacturer |

| Processing |

CNC milling and proprietary heat treatment process |

| Certification |

ISO9001 |

| MOQ |

No MOQ required for testing and trial order |

| Drill Rod Type |

Male-Male Rod, Male-Female Rod |

Applications

Underground mining extracts resources such as metal from underground deposits using specialized equipment including our high-performance drill rods.

Drifting and Tunneling

Drifting involves cutting linear passageways connecting underground extraction sites to the surface. Tunneling creates sealed tunnels for ore transportation.

Benching and Long Hole Drilling

Benching uses horizontal rock cuts to access deposits, while long hole drilling employs vertical shafts to reach deeper ore deposits.

Quarrying and Open Pit Mining

Quarrying extracts resources like limestone from shallow depths, while open pit mining creates large surface excavations to access deeper veins.

Support and Services

We provide comprehensive technical support for Thread Drill Rods including installation, maintenance, and repair services. Our experienced technicians offer 24/7 support and supply replacement parts to ensure continuous operation.

Frequently Asked Questions

Q1: What is the Brand Name of Thread Drill Rod?

A1: The Brand Name of Thread Drill Rod is MTH.

Q2: Where does Thread Drill Rod come from?

A2: Thread Drill Rod comes from China.

Q3: Is Thread Drill Rod certified?

A3: Yes, Thread Drill Rod is certified by ISO9001.

Q4: How is Thread Drill Rod packaged?

A4: Thread Drill Rod is packaged in wooden case or bundle.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!