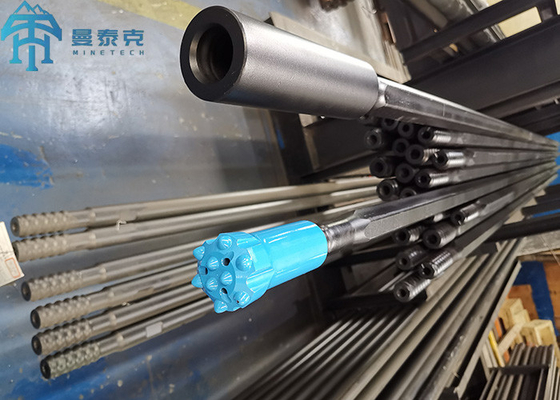

R25/R32/T38/T45/T51 Threaded Drill Rod Extension Rod MF Rock Drilling Tools

Features:

Extension rods are made by hollow drill steels. This hollow hole are usually named flushing hole, used for transmitting water or air during drilling.

And the threads can be used for connecting couplings, shanks, couplings or bits.

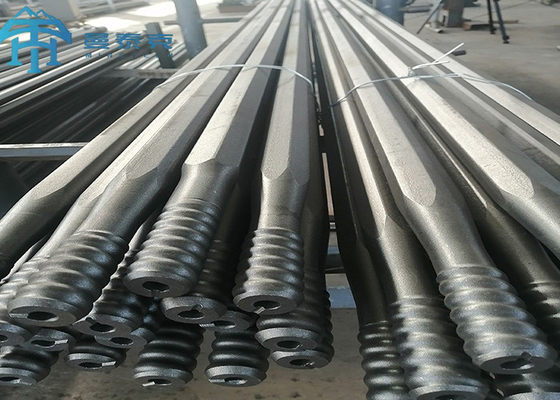

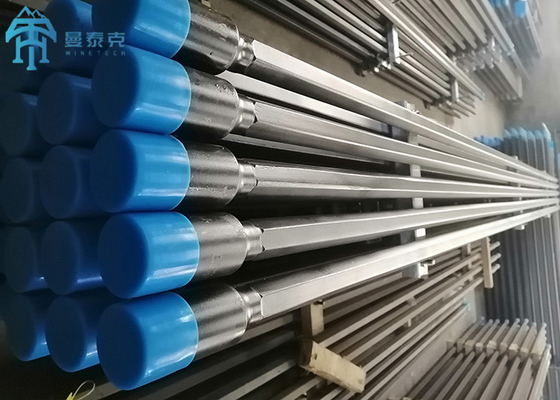

Body Type:

There are two shapes of extension rods, round type and hexagonal type.

Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing.

Round rods are generally lighter than hexagonal rods and are normally used in extension drilling applications.

Thread Type:

Usually for extension rods, there are R22, R25, R28, R32, R38, T38, T45, T51, ST58, T60 threads,

and different lengths of rods are available from 600mm to 6400mm usually.

Applications:

1. Underground mining

2. Dimensional Stone Industry

3. Tunneling,quarrying

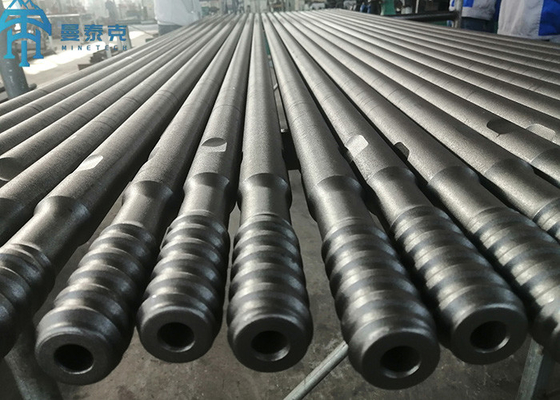

Description:

The new H22 integral brazing rod is a high quality taper brazing rod, brazing rod from billet selection to casting processing, all adopt foreign control standards, strictly control the quality source, refine the processing process, and continuously improve the quality and life of the product, is a sincere work to break through the self and give back to customers.

The new H22 brazing rod guarantees the high-end atmosphere of the product appearance, which is the embodiment of the product quality and vision. Longer life, more stable performance, giving you a more lasting use experience. To ensure stable performance, the rolling process of H22 brazing rod adopts temperature-controlled uniform organization rolling; thermal imaging temperature control setting is carried out in all thermal processing areas during processing to ensure the consistency of quality in all areas of brazing rod, effectively reducing the occurrence of various failure problems, extending service life and reducing input costs.

Specifications:

| Types of drill rods |

Specifications |

Length (mm) |

Shank |

Weight (kg) |

| Tapered drill rods |

Taper Angle: 4, 6, 7, 11, 12 degree |

400mm to 8000mm |

Hex22mm*108mm Hex25mm*159mm Hex19mm*108mm |

1.7 - 24.9 |

| Integral drill steel |

Bit diameter: 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm |

400mm to 4800mm |

3 – 15.4

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!