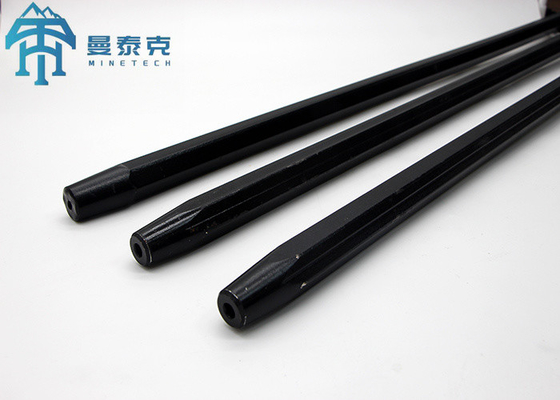

Full Carburized 12° Drilling Bar Hexagonal Drill Rods For Tunnelling and Drifting

Product Description:

Tapered Drill Rods: A Comprehensive Overview

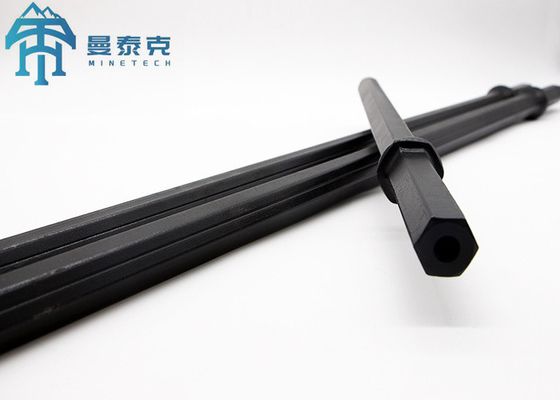

Tapered drill rods are widely used in shallow hole drilling operations carried out using small pneumatic rock drills or hydraulic rock drills. Generally made of H22 and H25 hexagonal hollow drill steel, tapered drill rods need to be connected to the taper drill bit for efficient rock drilling.

These rods are widely used in several fields, including, but not limited to, quarries, coal mines, roadbeds, and construction sites. With conventional taper angles ranging from 7°, 11°, and 12°, the choice of an appropriate angle would depend on the specific needs of the user.

Materials

As mentioned earlier, tapered drill rods are made of hexagonal hollow drill steel, specifically H22 and H25. These high-quality materials ensure that the drill rods are durable and reliable in their applications.

Applications

Tapered drill rods find extensive use in rock drilling operations, with applications in various fields as follows:

Quarries- for drilling stones, rocks and other geological samples

Coal mines- for drilling holes for mineworkers to carry out their duties

Roadbed construction- for drilling holes in hard-to-access areas

Construction sites- for drilling holes for the installation of posts, poles and other construction elements

Taper Angles

Tapered drill rods come in different taper angles ranging from 7°, 11°, and 12°. The right taper angle depends on the rock drilling operation and surface hardness.

Features:

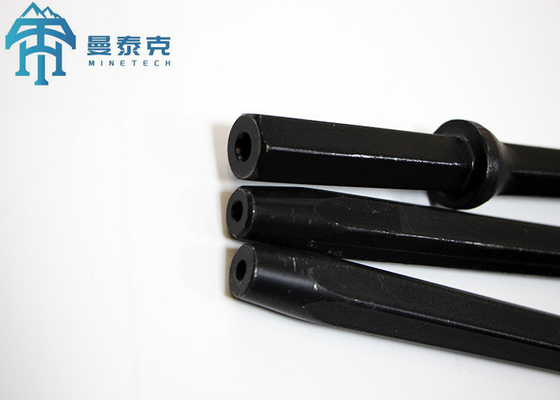

Workmanship

The Minetech tapered rod is treated with carburize, which enhances the durability and toughness of the material. The carburize treatment improves the surface hardness of the rod, making it resistant to wear and damage caused by drilling activities. This workmanship ensures that the Minetech tapered rod can withstand the harsh conditions of rock drilling and perform efficiently over a long period.

Tough and Durable Tapered Drill Rods

Our tapered drill rods are designed to withstand the tough conditions encountered during rock drilling. The rods play a critical role in transferring the percussion energy from the rock drill to the drilling bit and ultimately into the rock. As such, they are subjected to high bending stress and are prone to damage caused by the corrosive water used to flush the holes during drilling.

Despite these challenging conditions, our tapered drill rods are built to last. Constructed from high-quality materials and designed with precision, our rods deliver exceptional performance and reliability. Whether drilling deep into the earth or working in challenging surface conditions, our tapered drill rods are up to the task.

Technical Parameters:

| Length (mm) |

Length (foot/inch) |

Part Number |

Weight (kg) |

| 400 |

1'33/4'' |

TRH22L0400 |

1.7 |

| 800 |

2'71/2'' |

TRH22L0800 |

2.9 |

| 1830 |

6' |

TRH22L1830 |

6.0 |

| 2000 |

6'63/4'' |

TRH22L2000 |

6.5 |

| 2435 |

8' |

TRH22L2435 |

7.8 |

| 3050 |

10' |

TRH22L3050 |

9.9 |

| 3200 |

10'6'' |

TRH22L3200 |

10.1 |

| 4000 |

13'13/8'' |

TRH22L4000 |

12.7 |

| 4800 |

15'87/8'' |

TRH22L4800 |

15.1 |

| 5600 |

18'45/18'' |

TRH22L5600 |

17.5 |

| 6400 |

21' |

TRH22L6400 |

20.0 |

| 7200 |

23'71/4'' |

TRH22L7200 |

22.4 |

| 8000 |

26'23/4'' |

TRH22L8000 |

24.9 |

Applications:

Tapered drill rod is suitable for small pneumatic rock drills or hydraulic rock drills for shallow hole drilling operations, and are generally made of H22 and H25 hexagonal hollow drill steel. The tapered drill rod needs to be matched with the taper drill bit for rock drilling, and It is usually used in rock drilling operations in quarries, coal mines, roadbeds, construction and other fields like tunneling and drifting.

Company Profile

Hebei Minetech Machinery Technology Co, Ltd is an joint venture enterprise with Europe Partner, which is located in Shijiazhuang City, Hebei Province,China. Our company is specialized in manufacturing and exporting of mining machinery, such as hydraulic and pneumatic drill machine, roof bolter and drilling consumption ,like drill bit and drill rod with own factory in Shijiazhuang City.With our rich expenience for over a decade and with professional engineers andsales team, we focus on providing complete solutions for mining machinery.

Target markets is gradually shifted from domestic market to international market, products are exported to more than thirty countries and regions, including Southeast Asia, the United States, Germany, Britain, South Africa, Poland, Russia, Middle Asia, South America and so on, and established a good brand and reputation ininternational market.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!